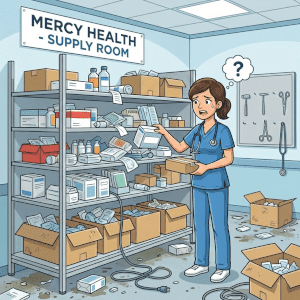

Hey everyone! Let’s talk about a hospital called Mercy Health (that’s not their real name, but let’s go with it). This place was a total mess. Medical supplies were everywhere, and it was actually getting dangerous.

The big bosses knew they had to do something to make patients safer and workers happier. So, they decided to try Lean 6S. This is a system designed to make work safer and easier by clearing out the clutter. Here is how their “Healing Journey” went down.

1. Sorting Through the Storm

At first, it was pure chaos. Doctors couldn’t find records, and supplies were just piled up in corners. The first step was Sort. A special team went through everything and asked, “Do we actually need this?” They threw away broken equipment and old junk that was just taking up space.

2. Finding a Home for Everything

The next step was Set in Order. It’s hard to save lives when you’re hunting for a bandage! To fix this, they used a genius idea: Color-Coding. Every department got its own color, so you could tell at a glance where a tray belonged. They also started using digital trackers so they’d know exactly when they were running low on medicine.

3. Making the Place Shine

In a hospital, being clean isn’t just about looks—it’s about germs! The Shine step was all about making a schedule. Instead of cleaning “whenever,” they set up daily routines and trained everyone on the best way to scrub down a room. Soon, the whole building was literally gleaming.

4. Making a "Master Recipe"

The biggest headache was that every department did things differently. It was super confusing! To fix this, they moved to Standardize. They brought in the most experienced workers to help write one “Master Recipe” for how tasks should be done. Now, no matter who is on shift, the work happens the same way every time.

5. Keeping the Habit Alive

The hardest part of any change is making it stick. People get tired or go back to their old, messy ways. To Sustain the progress, Mercy Health started a training program for every new person they hired. They even started rewarding workers who did a great job keeping their areas organized. It turned Lean into a habit, not just a one-time project.

6. Safety Above All Else

The final “S” is for Safety. They bought better equipment that wouldn’t hurt the nurses’ backs and did regular emergency drills. They also made it super easy for anyone to speak up if they saw something dangerous.

The Result?

By using 6S, Mercy Health turned a messy, stressful hospital into a calm, organized place where patients get better faster and the staff actually enjoys coming to work.

A Hospital Transformed

Through dedication, perseverance, and strategic problem-solving, Mercy Health overcame the obstacles and transformed into a beacon of efficiency and patient care. Lean 6S became more than a methodology; it became the hospital’s way of life.